Water Treatment Controllers

Enjoy unparalleled versatility and powerful programming for complete control of chemical metering pumps and valves in a broad range of water treatment applications

FEATURE PRODUCTS

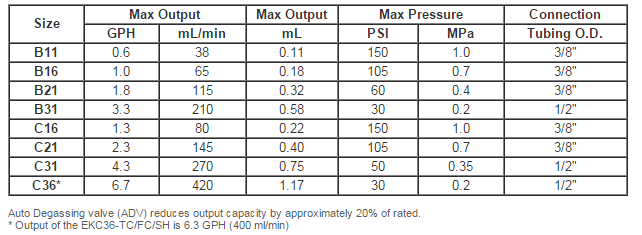

EHE Series 75.7 L / H @ 150 PSI

The EHE series have capacities up to 20 gallons per hour at 150 PSI. Combining performance and an adjustment ratio of 1800: 1, one of the most versatile pumps on the market today.

Metering and volumetric pumps EHE Series

– Control: Start / Stop (ON / OFF) – 4-20 mA – pulse input – Stop / Start external

Solenoid metering pump

This new series of metering and volumetric pumps can achieve a rate of 1.25L / min and, thanks to the integrated microprocessor, to manage a wide variety of current signals or pulses.

Metering and volumetric pump EH E – High Resolution

The volume injected is adjusted by means of frequency (between O and 360 strokes) and stroke length (20 to 100%), which makes possible a wide range of flow rates.

Metering and volumetric pump EH E – Integrated Microprocessor

The controller includes a microprocessor that allows four operating modes (manual, proportional divider and multiplier).

Dosing and volumetric pump EH E – Controller functions

Manual

The injection rate is increased or decreased by one stroke / minute in the range from 0 to 360. This setting can be carried out either on or off.

Proportional

The injection rate can be controlled by a flow of continuous type, 4-20mA, 0-20mA, 20-4 mA, 20-0mA.

Divider

in response to (n) pulses, the metering pump makes an injection. The number of pulses to be received is set by the keys between 1 and 999.

Multiplier

In response to a pulse, the dosing pump performs (n) injections. The number of injections is set by the keys between 1 and 999. The pump is able to memorize the pulses which occur during the execution of the previous command (maximum 250 pulses).

EJ Series

The EJ series provides accurate chemical injection at an economical price. Universal voltage capability allows 100 – 240VAC operation in virtually any country. The EJ series are compact, easy to use and have outputs at 1.3 GPH (LPH 4.8) and a maximum pressure of 175 PSI (1.2 MPa).

EWN

The Iwaki series EWN pumps are electronically controlled electrovalves driven units of measurement capable of very accurate and easy to control chemical dosing. Manual, semi-automatic or fully automatic control is possible by combining the appropriate flush-mounted control modules.

EZ Series 23.8 L / H @ 150 PSI

EZ series

solenoid metering pumps – Control: Start / Stop (ON / OFF)

Electromagnetic Dosing Pumps – EZ Series

This economical version allows precise dosing at the lowest cost. Manual operation or simple on-off remote control for conventional liquid injections.

EZ pumps benefit from the major advantages of the range and bring precision and reliability.

Solenoid metering pump EZ – High frequency of injection

With its injection rate reaches 360 beats per minute dosage is more regular.

Solenoid metering pump EZ – High accuracy

The accuracy of the flow rate is roughly 2%. Linearity is held within a range of plus or minus 3%. The frequency of injection is maintained at plus or minus 1%.

Solenoid metering pump EZ – Compact

Ideal for integrators, pumps EZ series are small in size, lightweight and silent.

Solenoid metering pump EZ – Double ball valve

The ball sets, seat and guide provide a complete seal and ensure the precision and good performance boot.

Electromagnetic metering pump EZ – Long Membrane

The membrane, PTFE on EPDM is molded on a steel core. A membrane reinforcement minimizes flow variations if pressure changes.

High Viscosity Series 15.0 L / H @ 73 PSI

The EH-HV series is specifically designed to handle high viscosity chemicals up to 20,000 cps. Equipped with springs and stainless steel balls.

Specialist supplier of water treatment equipment in

metering and volumetric pumps Series HV (High Viscosity)

– Controls: Start / Stop (ON / OFF) – 4-20 mA – pulse input – Stop / Start external

EH VH-series Designed specifically to inject precisely high viscosity chemicals.

Equipped with sturdy materials, PVC heads and stainless steel springs for check valves, the HV series is designed to give an action to these valves, a precise and durable performance.

Designed to pump with high precision products at 20,000 cps (unit of viscosity).

The HV series is available in two models:

EWN-R-HV: 8.69 l / h to 73 PSI

EHE-HV: 15.12 l / h to 50 PSI

Its exclusive two-year warranty on the entire pump, the EH-HV series is the perfect solution for your high viscosity applications.

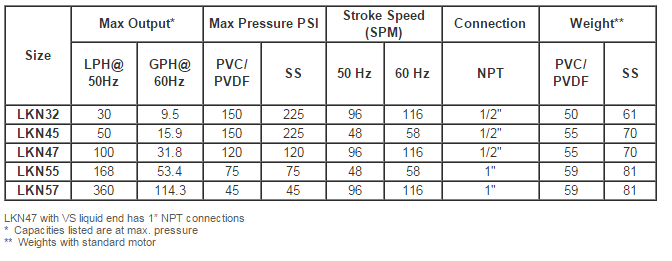

Serie LK 431.5 L/H @ 225 PSI

In a separate class – LK is a hydraulic diaphragm pump that can accommodate most electric motors.

Can easily add a variable speed controller.

Dosing and metering pumps LK

– Control: Start / Stop (ON / OFF) – 4-20 mA – pulse input – Stop / Start external

Diaphragm and electromagnetic dosing and volumetric pumps

The electromechanical LK diaphragm dosing pumps feature a dual cam system which makes them very reliable, compact and robust.

Thanks to its extensive experience in this field, IWAKI Co has developed all its know-how to create an ideal dosing pump for the chemical industry, water treatment, paper and food industry.

The prime qualities of this type of pump are performance, ease of use and low maintenance cost.

The flow rate of this volumetric pump is 2%.

The reproducibility is perfect thanks to the linearity of the shots and its accuracy. There is no variation in the flow time.

It is possible to adapt different types of motorization, either mono or sort and add variable speed variator.

This makes this series one of the most versatile at the most competitive prices in the industry.

Choice of engines – We supply engines (Brook Crompton or WEG and Variable Speed Variable WEG or according to your preferences.

Series EWN-Y + flow meter EFS

The EWN-Y series electromagnetic metering pump combined with EFS flow sensor provides accurate real-time control and flow display.

Dosing and metering pumps EWN-Y Series + EFS

– Control: Start / Stop (ON / OFF) – 4-20 mA – pulse input – Stop / Start external – Flow Verification – alarm relay

The new EWN-Y electromagnetic metering pump combined with EFS flow sensor provides accurate real-time control and flow display.

The required flow rate is simply entered into the pump. Thanks to feedback from the EFS sensor, the pump constantly adjusts its speed to maintain the dosage even under changing conditions of pressure, temperature, viscosity, suction or discharge.

The EFS is mounted directly on the pump and allows the digital display of the dosage per minute or per hour without any calibration.

The EWN-Y allows the sending of a proportional signal 4-20mA of the dosage, as well as the display of the operating history such as the total volume injected and the volume of liquid consumed over time.

Product Carousel Tabs

Stenner Peristaltic Pumps

The possibilities are endless with Stenner peristaltic metering pumps. Select from an array pumps with different operating controls, flow rate outputs, and operating pressure for applications such as oxidation, disinfection, pH control, or for the accurate injection of additives for a manufacturing or industrial process.

Peristaltic pumps have a great advantage when pumping chemicals like chlorine, peracetic acid and other product that grate air bubbles in the suction line of the pump.

Stenner Pumps – Built with A Strong Work Ethic

• Self-priming against maximum working pressure

• Can inject off-gassing solutions

• No vapor lock or loss of prime

• Tube replacement without tools

• Solid one piece tube construction

• Tube lubrication not required

• Three point roller design assist with anti-siphoning

• Output reproducibility

• Output volume not affected by back pressure

• Foot, prime or de-gassing valve not required

• Some model can pup up to 2500 CPS products

• Some models can detect tube failure

Disinfection

• Disinfection is necessary around the world to provide biologically safe drinking water to prevent waterborne diseases such as cholera, typhoid and dysentery.

• Sodium hypochlorite is a popular form of chlorine that is effective for disinfection and maintains a residual level throughout a commercial or residential plumbing system. Stenner pumps are not affected by off-gassing solutions and can inject chlorine at full strength or diluted with soft water.

SP-350P Tagged Polymer Handheld

The Pyxis SP-350P is a uniquely designed handheld multimeter that measures Fluorescent Polymer. It is a cuvette-less device. Less than 5 mL water sample is needed to fill the sample cell for proper measurement.

The Pyxis SP-350P is a uniquely designed handheld multimeter that measures Fluorescent Polymer. It is a cuvette-less device. Less than 5 mL water sample is needed to fill the sample cell for proper measurement.

The Pyxis SP-350P analyzer measures the concentration of Fluorescent Polymer of a water sample and includes the following features:

Pyxis Lab has a Continuous Improvement Policy, this means that this units specifications are subject to change at any time and without notice. However, it is only for the betterment of the unit! The Fluorescent Polymer concentration scale is based on the polymer containing 0.25 mole % fluorescent monomer.

Specifications

Optional Accessories

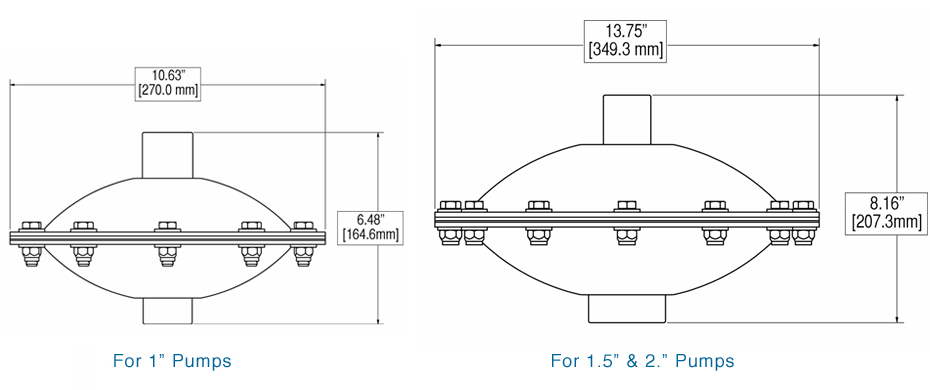

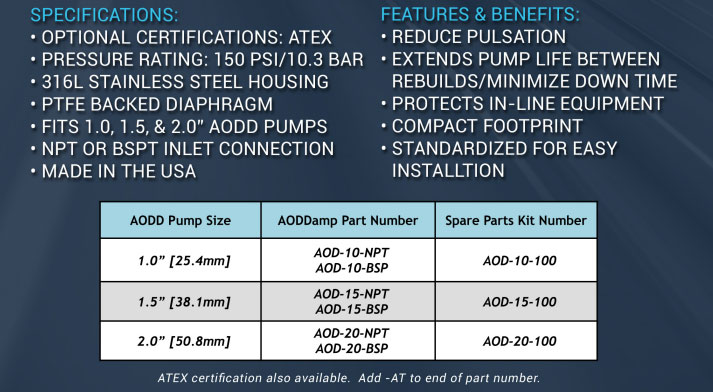

SENTRY Pulsation Dampeners & Arrestors

Dampeners and Suppressors

remove hydraulic shock and vibration, enhancing all-around performance and reliability of fluid flow applications.

remove hydraulic shock and vibration, enhancing all-around performance and reliability of fluid flow applications.

Positive Displacement (PD) pumps create pulsation and hydraulic shock due to the reciprocating nature of their stroking action, potentially damaging the entire pumping system.

BLACOH’s SENTRY Pulsation Dampeners & Surge Suppressors remove virtually all hydraulic shock, enhancing all-around performance and reliability of fluid flow in industrial and chemical transfer applications.

FDA compliant MATERIALS and easy to clean for sanitary or food applications.

Reduce pulsation, improve laminar flow, mitigate water hammer, shaking pipes, splashing, enhance pump performance and flow meter measurement.

SENTRY BENEFITS:

SENTRY FEATURES:

SANITARY PULSATION DAMPENERS

FDA compliant materials and easy to clean for sanitary or food applications.

Designed for sanitary applications in chemical, industrial, water treatment, pharmaceutical and food/beverage industries, the Blacoh sanitary line of pulsation dampeners and surge suppressors feature specialized stainless steel bodies and tri-clamp fittings. Blacoh’s pulsation dampeners can remove up to 99% of pulsation and vibration, enhancing all-around performance and reliability of fluid flow and protect the system from costly maintenance and repair. Reduce pulsation, improve laminar flow, mitigate water hammer, shaking pipes, splashing, enhance pump performance and flow meter measurement by using one of these units. FDA compliant materials available, including polished and bead blasted 316L stainless steel surfaces. Tri-clamp inlets, optional T-handles, and autoclave safe wetted components provide for easy cleaning.

Features:

Maximum Pressure: 1,000 psi (68.9 bar)

Capacity: 4 cu in – 5 gallon (.066 – 19 L)

Body Materials: 30 RA Polished 316L Stainless Steel

Bead Blasted 316L Stainless Steel

Temperature: -20°F to +350°F (-29 °C to +177°C)

Inlet Port: Tri-Clamp Sanitary Fitting

Air Control Options: Automatic, Adjustable, Chargeable

Bladder Options: Food-Grade Buna, Food-Grade

Silicone, Food-Grade EPDM, PTFE

Common Applications:

Sentinel Calibration Columns

Graduated Calibration Cylinders for Accurate Calibration of Chemical Metering Pumps

Blacoh SENTINEL Calibration Columns or Cylinders will enhance your feed systems by allowing verification of the flow rate of the feed pump.

Calibration Columns are installed on the suction side of the metering pump and are isolated with two valves installed with the cylinder.

The top of the cylinder is vented back to the supply tank or drain. The calibration cylinder is filled to the top mark then the valve from the tank is closed. Turning on the metering pump will draw down the liquid providing a simple means to verify the accuracy of the pump flow rate. USGPH (Gallons Per Hour) and ML are shown on the cylinder.

Blacoh SENTINEL Calibration Columns are critical to accurate determination of your system flow rate, either at start-up or following maintenance. They are offered in clear PVC or Borosilicate glass. Max cylinder pressure is 15psi.

Sentinel Injection Quills

Inject Quills for safe delivery of chemicals into pipelines

Blacoh SENTINEL Injection Quills are used to provide safe delivery of chemicals into pipelines. The quill end ensures the dispersion of the chemicals away from the pipe wall. The integral spring loaded check valve prevents backflow from the pressurized pipe if there is a break in the discharge piping. A union connection on the inlet allows for ease of installation and maintenance.

Options & Benefits:

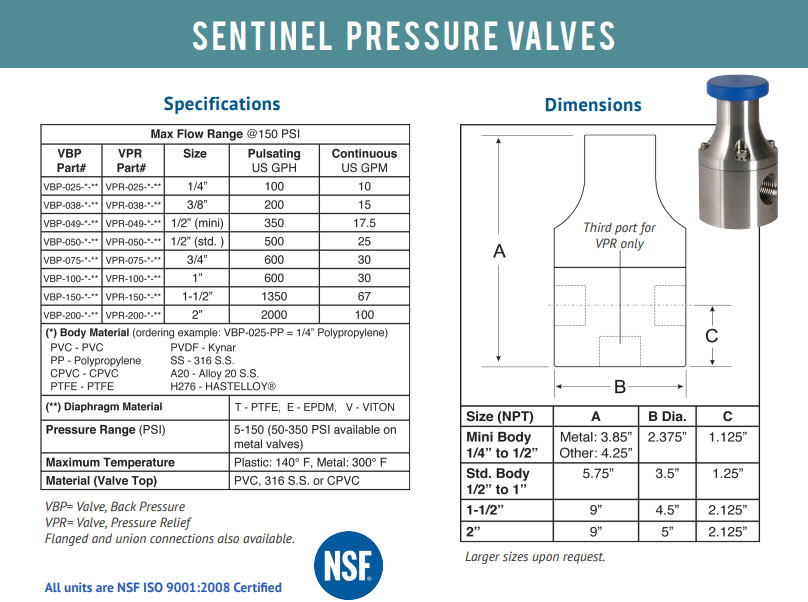

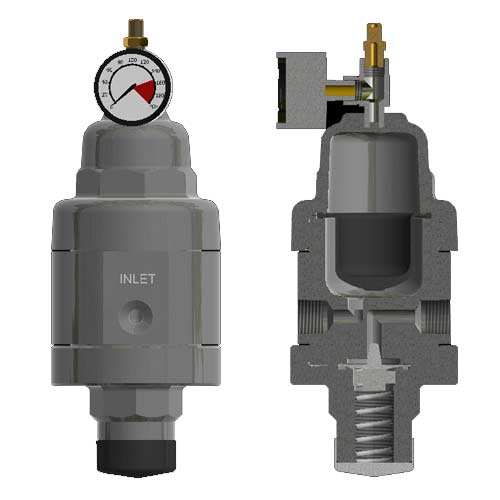

SENTINEL Diaphragm Back Pressure Valves

Prevent siphoning and stabilize dosage rates with SENTINEL Diaphragm Back Pressure Valves

Diaphragm back pressure valves are designed to enhance the performance of pumping systems by applying a continuous back pressure to the system pump, while also acting as an anti-syphon valve. Robust construction ensures reliability in the rigorous service of municipal and industrial applications.

Diaphragm back pressure valves apply positive discharge pressure to a metering pump system to prevent siphoning and eliminate varying dosage rates caused by fluctuating downstream pressure. The diaphragm is held against the valve seat by an internal spring. When the preset pressure is exceeded, the diaphragm is forced up and system fluid flows through the valve to the injection point. The valves are preset for 50 psi, however they are field adjustable from 5 to 150 psi, (optional up to 350 psi for high pressure) via the adjustment screw. Installation should be as close to the injection point as possible to prevent system line drainage, and it is most important that all pumping system equipment such as pulsation dampeners and pressure gauges are between the pump and back pressure valve

Air Operated Double Diaphragm Systems

Introducing Blacoh's all-new pulsation dampener designed

specifically for AODD pumps.

When it comes to dampeners for AODD pumps, you don't have to sacrifice quality for price. Backed by the name you know and trust, our new AODDampener is a market-responsive quality product that improves the performance of your system, reduces water hammer and the common shaking of pipes caused by AODD pumps.

With its universal materials: 316 Stainless Steel and PTFE backed diaphragm, these units will cover almost all fluid applications and can be easily used in a full range of system materials from plastics to metals.

Watch the videos below to see the dampener’s performance and benefits in action.

Proven Performance

We are dedicated to providing you with the most competitive pricing while still maintaining that the AODDampener is quality sourced, manufactured and assembled to ISO 9001:2008 standards here in the United States.

Extensively tested and rated to maximum pressure of 150 PSI (10.3 bar).

Improve your AODD pumping performance, reduce harmful vibrations and save on overall energy cost of your system

Fully Automatic Air Control

Fully Automatic Air Control

Our newly designed fully automatic air control is connected internally to the diaphragm and automatically adjusts when needed.

Low Air Consumption:

When connected to a plant air supply line, the fully automatic air control only takes the air needed to adjust to the change in pump discharge pressure.

available in two sizes for convenient stocking

Valve Hybride – Blacoh

l'avenir des systèmes de pompes doseuses. Présentation du premier amortisseur de pulsations combiné au monde et soupape de pression noire.

La nouvelle Hybrid Valve ™ de Blacoh, en attente de brevet, associe le contrôle constant du débit d'un amortisseur de pulsations et la régulation d'une vanne de contre-pression pour fournir les performances et les fonctionnalités des deux. Pourquoi installer et entretenir deux équipements lorsque le Hybrid Valve ™ fait la même chose, mais seulement mieux.

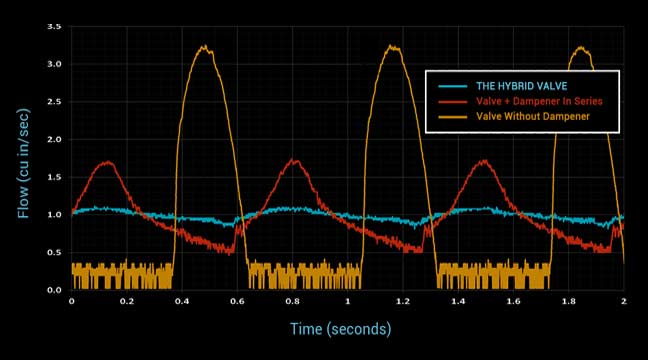

PERFORMANCE: LES CHIFFRES SONT INDÉNIABLE

La soupape hybride en instance de brevet a été conçue selon des principes éprouvés avec une conception de pointe pour des performances optimales et une efficacité maximale.

Dans un système de pompe doseuse, l'utilisation d'une soupape de contre-pression seule (orange) n'améliore en rien le débit de fluide. Lorsqu'il est mis en série avec un amortisseur de pulsations, le débit s'améliore de manière significative (rouge), mais les résultats ne peuvent toujours pas égaler les performances de la vanne hybride à construction unique pour le flux le plus stable (bleu).

Faites confiance aux experts en contrôle des fluides

L'emplacement et la proximité sont essentiels lors de l'installation d'amortisseurs de pulsations et de vannes de contre-pression dans tout système de pompage. Une soupape de surpression installée en série avec un amortisseur peut annuler l'effet d'amortissement si la soupape s'ouvre et se ferme avant que l'amortisseur ne puisse capter une impulsion complète. Cet effet d'ouverture rapide peut également générer trop de gain dans la soupape de contre-pression, ce qui entraîne une inefficacité et des bruits de claquement.

En combinant l’amortisseur et la soupape de surpression dans une seule unité technique, nous avons éliminé les problèmes les plus courants liés à l’installation pour un système plus efficace et simplifié.

VOIR LE HYBRIDE EN ACTION

Regardez notre directeur de l'ingénierie David McComb démontrer la Hybrid Valve ™ avec une pompe doseuse.

Il vous guidera à travers les performances de la pompe avec un amortisseur de pulsations seul, puis en série avec une soupape de contre-pression et enfin avec la nouvelle Hybrid Valve ™.

Comprendre les principes de la dynamique des fluides pour voir pourquoi la Hybrid Valve ™ offre les meilleures performances et donne à votre système la protection qu'il mérite.

Blacoh Hybrid Valve

The future of metering pump systems. Introducing the world's first combination pulsation dampener & back pressure valvve:

The new patent-pending Hybrid Valve™ from Blacoh combines the steady flow control of a pulsation dampener and the regulation of a back pressure valve to deliver the performance and functionality of both. Why install and maintain two pieces of equipment when the Hybrid Valve™ does the same- only better.

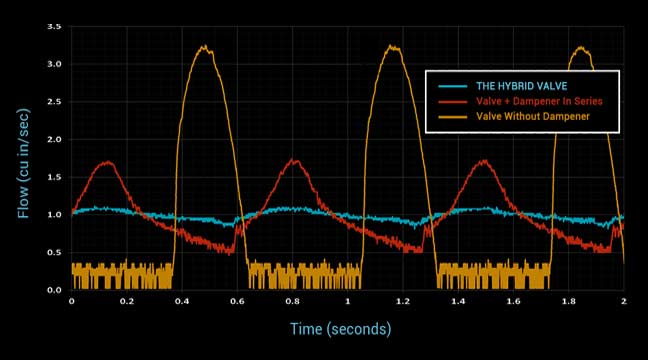

PERFORMANCE: THE NUMBERS ARE UNDENIABLE

The patent-pending Hybrid Valve was engineered to proven principles with state-of-the-art design for optimum performance and maximum efficiency.

In a metering pump system, using a back pressure valve alone (orange) does nothing to improve fluid flow. When put in series with a pulsation dampener, the flow improves significantly (red) but, results still can’t match the performance of the single construction Hybrid Valve for the steadiest flow (blue).

TRUST THE FLUID CONTROL EXPERTS

Location and proximity are key when installing pulsation dampeners and back pressure valves in any pumping system. A back pressure valve installed in series with a dampener can negate the dampening effect if the valve is opening and closing before the dampener is able to capture a full pulse. This quick-opening effect can also create too much gain within the back pressure valve resulting in inefficiency and chatter.

By combining the dampener and back pressure valve into a single engineered unit, we’ve eliminated the most common issues with installation for a more efficient, simplified system.

SEE THE HYBRID IN ACTION

Watch our Engineering Manager David McComb demonstrate the Hybrid Valve™ with a metering pump.

He will guide you through the performance of the pump with a pulsation dampener alone, then in series with a back pressure valve, and finally with the new Hybrid Valve™.

Understand the fluid dynamic principles to see why the Hybrid Valve™ delivers the best performance and giving your system the protection that it deserves.

Plating Controllers

Copper/Nickel Plating Controllers

Walchem’s WCU410 Copper Controller and WNI Nickel Controller are optoelectronic on-line analyzers that measure the actual concentration of copper or nickel in solution. They are used in a variety of applications including electroless plating baths and microetch baths (including oxide-replacement types).

Concentration Read in Units

Concentration set point, alarm set points (high and low), dead band and pump on time are all easily adjustable.

Download stored data from the controller to a USB stick. Use the data to simply and easily validate system performance. The data and event logs show copper or nickel values, as well as accumulated chemical feed and relay activation times.

Four Separate Control Relays & Outputs (WCU )may be used to add copper, caustic, formaldehyde or chelator/stabilizer chemistries.

Optional pH Input Board (WNI) may be used to add pH adjustment chemistry.

– Output has a replenishment totalizer which may be set in units of time or volume.

EHE Series 75.7 L / H @ 150 PSI

The EHE series have capacities up to 20 gallons per hour at 150 PSI. Combining performance and an adjustment ratio of 1800: 1, one of the most versatile pumps on the market today.

Metering and volumetric pumps EHE Series

– Control: Start / Stop (ON / OFF) – 4-20 mA – pulse input – Stop / Start external

Solenoid metering pump

This new series of metering and volumetric pumps can achieve a rate of 1.25L / min and, thanks to the integrated microprocessor, to manage a wide variety of current signals or pulses.

Metering and volumetric pump EH E – High Resolution

The volume injected is adjusted by means of frequency (between O and 360 strokes) and stroke length (20 to 100%), which makes possible a wide range of flow rates.

Metering and volumetric pump EH E – Integrated Microprocessor

The controller includes a microprocessor that allows four operating modes (manual, proportional divider and multiplier).

Dosing and volumetric pump EH E – Controller functions

Manual

The injection rate is increased or decreased by one stroke / minute in the range from 0 to 360. This setting can be carried out either on or off.

Proportional

The injection rate can be controlled by a flow of continuous type, 4-20mA, 0-20mA, 20-4 mA, 20-0mA.

Divider

in response to (n) pulses, the metering pump makes an injection. The number of pulses to be received is set by the keys between 1 and 999.

Multiplier

In response to a pulse, the dosing pump performs (n) injections. The number of injections is set by the keys between 1 and 999. The pump is able to memorize the pulses which occur during the execution of the previous command (maximum 250 pulses).

ST-730 Series are designed for monitoring the middle range turbidity in various applications. It is more robust and tolerant to fouling, particular matters, and air bubbles comparing to other online turbidity meters designed for relatively clean water applications.

It also offers desired resolution and accuracy comparing to high turbidity or commonly referred to as suspended solid meters (4000 to 9999 NTU).

ST-730 series turbidity probe measures two optical densities and two scattering intensities at two wavelengths. This helps measure a large turbidity range and yet maintain a fine resolution. This design also helps the probe run self-diagnoses.

Typical Applications

Features

Specifications

| ST-730 | ST-731 | ST-730B | ST-735 | |

|---|---|---|---|---|

| Range | 0~100 NTU | 0-10 NTU | 0~500 NTU | 0~4,000 NTU |

| Resolution | 0.1 NTU | 0.05 NTU | 1 NTU | 10 NTU |

| Accuracy | ±2% of reading or 1 NTU whichever is greater | |||

| Method | Nephelometric, with light sources of White LED and IR LED (860nm) | |||

| Power Supply | 22-26V DC, Power Consumption ~1W | |||

| Outputs | Isolated 4-20mA Analog Output Isolated RS-485 Digital Output, Supporting MODBUS protocol |

|||

| Dimension | Length 6.8 inch, body diameter 1.44 inch | |||

| Weight | 0.37 pounds | |||

| Installation | Custom tee with 3/4” NPT ports | |||

| Material | CPVC | |||

| Pressure | Up to 100 psi | |||

| Temperature | Operation 40-120 °F, Storage 20~140 °F | |||

| Cable Length | 5 feet, terminated with IP67 connectors. 30 feet, 60 feet extension cables available |

|||

| Calibration | Two point calibration against standard solutions | |||

| Rating | IP66 | |||

| Regulation | CE marked | |||

Motor 1/2 to 5 HP Max. 500 L / min

Centrifugal pumps with magnetic drive – self-priming

pumps of the series SMX- (F) are centrifugal pumps with magnetic drive self-priming horizontal-type made of polypropylene or ETFE no metal parts in contact with the liquid. These pumps have a separation system to automatically evacuate air from the liquid and do not require priming pots or foot valves. They have a fast priming system and high performance. These pumps offer superior dry resistance to standard self-priming pumps.

Maximum capacity: Up to 500 L / min

Magnetic Pump SMX-F – Self-priming Pump

This magnetic drive pump, made without any metal parts in contact with the liquid, is self priming. It is sufficient to initially fill the reserve of liquid integrated in the pump body to ensure priming.

Magnetic Pump SMX-F – Simple construction

The main parts of this magnetic pump are common to the MX series (-F). The small quantity of parts makes it easier to maintain and manage spare parts.

Magnetic Pump SMX-F – Chemical Resistance

The parts of the wetted part are made of polypropylene filled with glass fibers, ETFE filled with carbon fibers, ceramic, carbon and other materials also resistant to corrosion. The SMX series of magnetic pumps can be used for a wide range of chemicals.

Série FT

Les contrôleurs de série FT400 sont indicateur à base de microcontrôleur qui interface avec les débits mètre sortie impulsion pour calculatrice et de débit instantané, le débit total et également générateur de signaux de sortie représentatif aux débits mesuré.

SP-350P Tagged Polymer Handheld

The Pyxis SP-350P is a uniquely designed handheld multimeter that measures Fluorescent Polymer. It is a cuvette-less device. Less than 5 mL water sample is needed to fill the sample cell for proper measurement.

The Pyxis SP-350P is a uniquely designed handheld multimeter that measures Fluorescent Polymer. It is a cuvette-less device. Less than 5 mL water sample is needed to fill the sample cell for proper measurement.

The Pyxis SP-350P analyzer measures the concentration of Fluorescent Polymer of a water sample and includes the following features:

Pyxis Lab has a Continuous Improvement Policy, this means that this units specifications are subject to change at any time and without notice. However, it is only for the betterment of the unit! The Fluorescent Polymer concentration scale is based on the polymer containing 0.25 mole % fluorescent monomer.

Specifications

Optional Accessories

EJ Series

The EJ series provides accurate chemical injection at an economical price. Universal voltage capability allows 100 – 240VAC operation in virtually any country. The EJ series are compact, easy to use and have outputs at 1.3 GPH (LPH 4.8) and a maximum pressure of 175 PSI (1.2 MPa).