Motor 1/2 to 5 HP Max. 500 L / min

Centrifugal pumps with magnetic drive – self-priming

pumps of the series SMX- (F) are centrifugal pumps with magnetic drive self-priming horizontal-type made of polypropylene or ETFE no metal parts in contact with the liquid. These pumps have a separation system to automatically evacuate air from the liquid and do not require priming pots or foot valves. They have a fast priming system and high performance. These pumps offer superior dry resistance to standard self-priming pumps.

Maximum capacity: Up to 500 L / min

Magnetic Pump SMX-F – Self-priming Pump

This magnetic drive pump, made without any metal parts in contact with the liquid, is self priming. It is sufficient to initially fill the reserve of liquid integrated in the pump body to ensure priming.

Magnetic Pump SMX-F – Simple construction

The main parts of this magnetic pump are common to the MX series (-F). The small quantity of parts makes it easier to maintain and manage spare parts.

Magnetic Pump SMX-F – Chemical Resistance

The parts of the wetted part are made of polypropylene filled with glass fibers, ETFE filled with carbon fibers, ceramic, carbon and other materials also resistant to corrosion. The SMX series of magnetic pumps can be used for a wide range of chemicals.

Related products

-

Iwaki centrifugal Mag drive pumps

Motor 1/2 to 5 HP Max. 600 L / min

0 out of 5(0)The pumps of the MXM series complete the range of process pumps and thus offer an additional choice in the range of centrifugal pumps with magnetic drive. The new MXM series offers the technical characteristics needed for a chemical pump, such as corrosion resistance, durability and safety.

Maximum capacity: Up to 605 L / min

The MXM series pumps complete the range of process magnetic pumps and enable IWAKI to offer an additional choice in its range of centrifugal pumps with magnetic drive.

MXM Magnetic Pump – Improved resistance to harsh operating conditionsThe “no contact” system and the “radial flow” construction improves dry running resistance and operation at low suction conditions.

Magnetic Drive Pump MXM – non-contact system

as conventional centrifugal pumps magnetic drive, the MXM series is scheduled to avoid contact with the bearing backstop during operations or dry air to the suction inlet. Thanks to this system, the risks of friction and heating with the melting of plastic materials are eliminated.Magnetic pump MXM – Construction “radial flow” (International Patent)

The principle of the radial movement of the magnetic pump allows circulation of the liquid between the shaft and the bearing through holes in the turbine and the magnetic capsule. This prevents heating due to friction between the shaft and bearing. As a result, thermal deformation is avoided.Magnetic pump MXM – exceptional corrosion resistance

The series of magnetic pumps MXM employs optimum corrosion materials such as ETFE reinforced carbon fiber (CFRETFE). High quality ceramic and carbon are used for the parts coming into contact with the liquid. The most appropriate turbine size and engine power can be selected according to the properties of the pumped liquid.Magnetic Drive Pump MXM – Robust Construction

The body forward CFRETFE a reinforcement iron. The assembly is intended to withstand high stresses for use in cement process.Magnetic Drive Pump MXM – Enhanced security

The rear body of the magnetic pump MXM features a unique design in its manufacture to resist deformation. A reinforcement of rear body makes it possible to increase the resistance to the hydraulic pressure and the mechanical forces on the support of the axis. The safety is thus reinforced by preventing the deformation of the rear body and the leakage of liquid.SKU: n/a -

Iwaki centrifugal Mag drive pumps

Flow rates between 5 L / min and 135 L / min

0 out of 5(0)The MX series, the first series to benefit from this latest innovation (international patent), comes in 10 models with flow rates up to 852 liters / minute and pressures up to 38 meters from Liquid Column.

SKU: n/a -

Iwaki centrifugal Mag drive pumps

Motor 2 to 25 HP Max. 1325 L / min

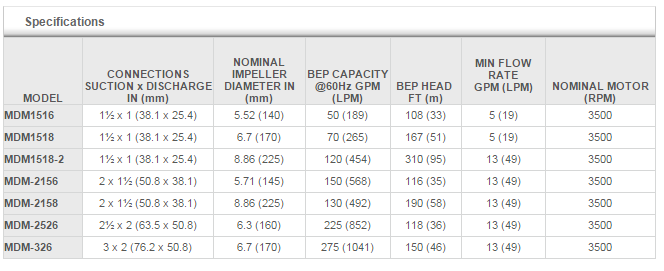

0 out of 5(0)MDM pumps are magnetic centrifugal pumps developed for a wide range of applications. The turbine in the volute (front body) is rotated by a magnetic force to transfer the liquid from the suction to the discharge of the pump. MDM pumps have excellent corrosion resistance, a long service life, high

safety and are used for pumping chemicals in different applications. Many chemicals can be transferred by these pumps.Maximum Capacity: Up to 1325 L / min

Specialist and supplier of water treatment equipmentInnovative, the Magnetic Pump series MDM brings notable progress in terms of comfort, safety of use and respect for the environment. It contributes to substantial savings due to its robustness and reliability by minimizing downtime and requiring little maintenance.

MDM Magnetic Pump – An Exclusive Mechanism for Preventing Dry Running

This magnetic pump is equipped with a device to avoid the effects of dry operation. The exceptional power of the magnets used (in rare earths) avoids contact of the magnetic capsule with the backstop and eliminates the risk of friction and heating due to melting of synthetic materials. This device achieves better resistance against dry running compared to traditional magnetic pumps.

Note: Only CF type magnetic pumps (with high density carbon bearings) can withstand dry operation. The latter is to be avoided in the case of parts of type KK (silicon carbide).Magnetic pump MDM – Components of extreme reliability

The front body ETFE is reinforced with carbon fibers for improved both strength and corrosion while the outer peripheral surfaces are reinforced with ductile iron to a more Long life.For the PFA MDM series, the ductile iron front body consists of a single piece coated with virgin fluorinated resin.

A new concept was adopted for the construction of the turbine. It is a “peg-fit” system that optimizes the axial maintenance of the turbine. Closed turbines are designed to ensure high efficiency. In addition, the rear body made of carbon-filled fluorine-containing resin is resistant to a pressure of 16 bar. It eliminates eddy currents and the production of sparks. Moreover, when dismantling for maintenance, any leakage of product proves impossible, the front and rear bodies being held in place by a flange. This advantage also contributes to respect for the environment.Magnetic Drive Pump MDM – release rear System (Pull-Back)

A special removal system is intended to facilitate maintenance of the magnetic pump. The interior of the unit can be easily inspected and parts can be replaced without disassembling the piping. This device is designed to prevent any leakage of liquid during the extraction of the motor assembly, spacer and magnetic drive SKU: n/a

SKU: n/a -

Iwaki centrifugal Mag drive pumps

Motor 15 to 100 HP Max. 4996 L / min

0 out of 5(0)Magnetic pump MDW Series

Centrifugal pumps with magnetic drive

magnetic pump MDW – Long life and increased reliabilityMaximum capacity: Up to 4996 L / min

All parts in fluorinated resins are lined with metal. Only the reinforcement of the rear bowl is made of PPS reinforced with fiberglass to resist the strongest stresses. The use of ductile iron to reinforce the front body and the spacer allowed the use of the MDW series magnetic pump in petrochemicalsMagnetic pump MDW – High corrosion resistance

These magnetic pumps are manufactured mainly fluorine resin and CIS. Standard body in ETFE, PFA for products specific to the electronics industry.Magnetic pump MDW – Liquids preserved

Pure fluorinated resins used avoid contamination of fluids especially in the middle of the semiconductor. The use of PFA makes it possible to use it with liquids whose temperature can exceed 120 ° C.Magnetic pump MDW – Dismantling and Maintenance Simplified

Dismantling the rear of the magnetic pump allows audits and interventions without dismantling the piping. The wear parts (bearing, sleeve, stop) can be replaced individually without special tools.SKU: n/a -

Iwaki centrifugal Mag drive pumps

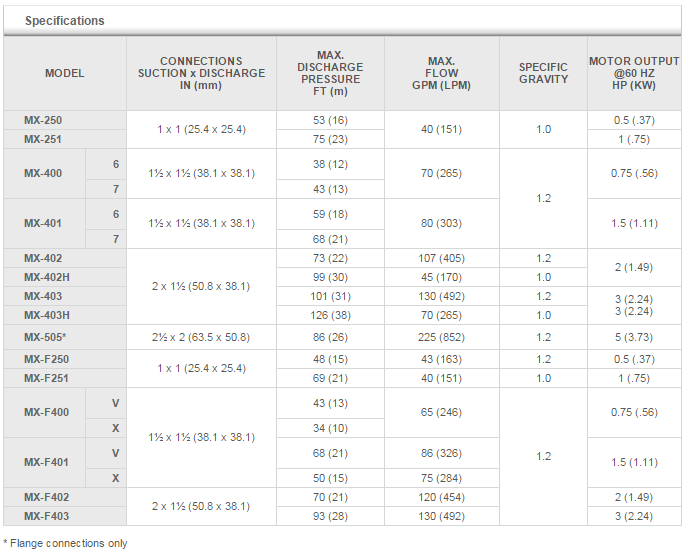

Motor 1/2 to 5 HP Max. 852 L / min

0 out of 5(0)The MX series, the first series to benefit from this latest innovation (international patent), comes in 10 models with flow rates up to 852 liters / minute and pressures up to 38 meters from Liquid Column.

Maximum capacity: Up to 852 L / min

Specialist and supplier of water treatment equipmentMX Magnetic Pump (-F) – Radial Flow Structure

The magnetic pumps in this series benefit from a new radial flow structure developed by IWAKI Co (international patent), which in conjunction with the principle of “contactless” and axle holding at the front and The rear, improves the life of the pump.

These technical innovations make it possible to resist abnormal operations such as cavitation and closed valve operation at discharge. The principle of the radial circulation of the magnetic pump offers a better circulation of the liquid around the shaft and the bearing thanks to the orifices located on the turbine and on the magnetic capsule which reduce the heat resulting from the friction of these elements. As a result, thermal deformation or melting is avoided.

MX magnetic pump (-F) – Body division (or volute) in 2 parts

This other innovation, developed by IWAKI Co (international patent), is based on the division of the body (or volute) into 2 parts (a front body and a rear body) forming a conical tangential chamber which guides the fluid towards the orifice of Refoulement. This improves performance by minimizing leakage inside the volute. Furthermore, all stressed parts of the magnetic pump (front and rear bodies, for example) are reinforced by ribs in order to improve their resistance to pressure and their mechanical strength.

SKU: n/a

SKU: n/a