Sentinel Injection Quills

Inject Quills for safe delivery of chemicals into pipelines

Blacoh SENTINEL Injection Quills are used to provide safe delivery of chemicals into pipelines. The quill end ensures the dispersion of the chemicals away from the pipe wall. The integral spring loaded check valve prevents backflow from the pressurized pipe if there is a break in the discharge piping. A union connection on the inlet allows for ease of installation and maintenance.

Options & Benefits:

- Injection quill can also be configured for use as an in-line check valve.

- Available in PVC, CPVC, PVDF, PP, 316 stainless steel, and other materials upon request

- Removable check valve seat

- Union inlet w/ Viton o-ring

- EPDM o-ring option available.

- Standard max pressures to 150 PSI

- Temperatures to 500º F

- Inlet tubing connector options available

- NPT or BSP process connections available

- Quill sizes: 0.5-2”

- 4” quill length standard with adders up to 8.5”

Related products

-

Blacoh

Air Operated Double Diaphragm Systems

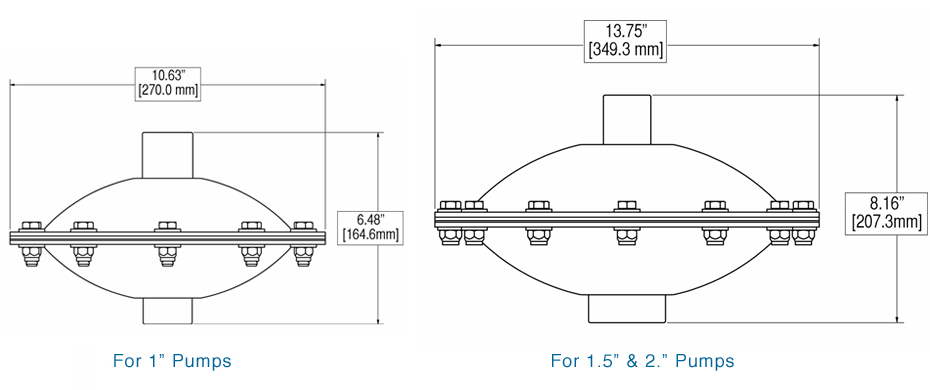

0 out of 5(0)Introducing Blacoh's all-new pulsation dampener designed

specifically for AODD pumps.

When it comes to dampeners for AODD pumps, you don't have to sacrifice quality for price. Backed by the name you know and trust, our new AODDampener is a market-responsive quality product that improves the performance of your system, reduces water hammer and the common shaking of pipes caused by AODD pumps.With its universal materials: 316 Stainless Steel and PTFE backed diaphragm, these units will cover almost all fluid applications and can be easily used in a full range of system materials from plastics to metals.

Watch the videos below to see the dampener’s performance and benefits in action.

Proven Performance

We are dedicated to providing you with the most competitive pricing while still maintaining that the AODDampener is quality sourced, manufactured and assembled to ISO 9001:2008 standards here in the United States.

Extensively tested and rated to maximum pressure of 150 PSI (10.3 bar).

Improve your AODD pumping performance, reduce harmful vibrations and save on overall energy cost of your system

Fully Automatic Air Control

Fully Automatic Air ControlOur newly designed fully automatic air control is connected internally to the diaphragm and automatically adjusts when needed.

Low Air Consumption:

When connected to a plant air supply line, the fully automatic air control only takes the air needed to adjust to the change in pump discharge pressure.available in two sizes for convenient stocking

SKU: n/a

SKU: n/a -

Blacoh

SENTRY Pulsation Dampeners & Arrestors

0 out of 5(0)Dampeners and Suppressors

remove hydraulic shock and vibration, enhancing all-around performance and reliability of fluid flow applications.

remove hydraulic shock and vibration, enhancing all-around performance and reliability of fluid flow applications.

Positive Displacement (PD) pumps create pulsation and hydraulic shock due to the reciprocating nature of their stroking action, potentially damaging the entire pumping system.BLACOH’s SENTRY Pulsation Dampeners & Surge Suppressors remove virtually all hydraulic shock, enhancing all-around performance and reliability of fluid flow in industrial and chemical transfer applications.

FDA compliant MATERIALS and easy to clean for sanitary or food applications.

Reduce pulsation, improve laminar flow, mitigate water hammer, shaking pipes, splashing, enhance pump performance and flow meter measurement.

SENTRY BENEFITS:

- Whether a piston, plunger, air diaphragm, peristaltic, gear, or diaphragm metering pump, a SENTRY Pulsation Dampener placed at the pump’s discharge will produce a near steady fluid flow up to 99% pulsation and vibration free

- Protects pipes, valves, fittings, meters, and in-line instrumentation from destructive pulsations, surges, cavitation, thermal expansion, and water hammer

- Creates steady and continuous flow when dosing, blending or proportioning additives

- Ensures accuracy, longevity, and repeatability of in-line meters

- Enables uniform application of material in spraying and coating systems

- Reduces product agitation, foaming, splashing and degradation of product

- Provides liquid energy storage for emergency valve closure and other equipment shutdown

- Reduces overall energy cost with continuous flow, rather than start/ stop flow

- Operates as a reservoir for make-up fluid

SENTRY FEATURES:

- Models in stock for all positive displacement pumps with discharge sizes from 1/8″ (3.18mm) to 6″ (152.4mm)

- Simple, reliable design and quick installation

- Easy in-line maintenance

- Pressure ranges up to 10,000 psi (689.4 bar) available from stock

- Temperature ranges from -60°F to +400°F (-51°C to +205°C) available from stock

- Custom models, larger sizes and higher pressure ratings available on request. Contact Blacoh for more information.

- Bodies available in a full range of chemically resistant materials

- Bladders available for even the most corrosive applications

SKU: n/a -

Blacoh

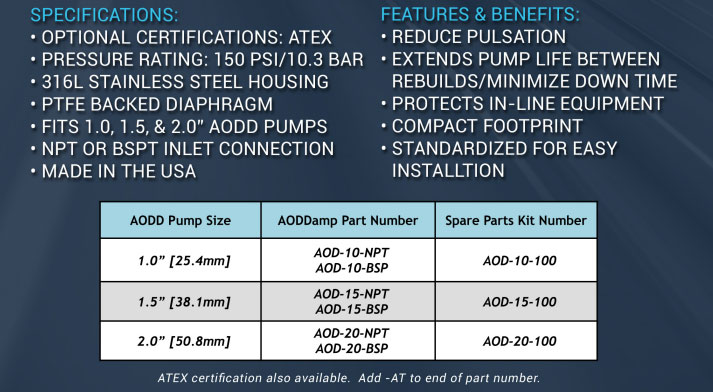

Valve Hybride – Blacoh

0 out of 5(0)l'avenir des systèmes de pompes doseuses. Présentation du premier amortisseur de pulsations combiné au monde et soupape de pression noire.

La nouvelle Hybrid Valve ™ de Blacoh, en attente de brevet, associe le contrôle constant du débit d'un amortisseur de pulsations et la régulation d'une vanne de contre-pression pour fournir les performances et les fonctionnalités des deux. Pourquoi installer et entretenir deux équipements lorsque le Hybrid Valve ™ fait la même chose, mais seulement mieux.

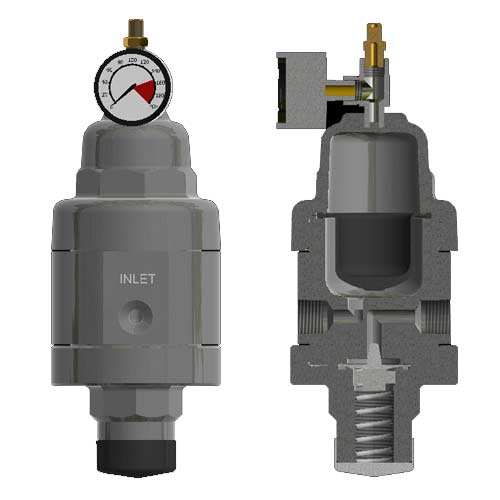

PERFORMANCE: LES CHIFFRES SONT INDÉNIABLE

La soupape hybride en instance de brevet a été conçue selon des principes éprouvés avec une conception de pointe pour des performances optimales et une efficacité maximale.

Dans un système de pompe doseuse, l'utilisation d'une soupape de contre-pression seule (orange) n'améliore en rien le débit de fluide. Lorsqu'il est mis en série avec un amortisseur de pulsations, le débit s'améliore de manière significative (rouge), mais les résultats ne peuvent toujours pas égaler les performances de la vanne hybride à construction unique pour le flux le plus stable (bleu).

Faites confiance aux experts en contrôle des fluides

L'emplacement et la proximité sont essentiels lors de l'installation d'amortisseurs de pulsations et de vannes de contre-pression dans tout système de pompage. Une soupape de surpression installée en série avec un amortisseur peut annuler l'effet d'amortissement si la soupape s'ouvre et se ferme avant que l'amortisseur ne puisse capter une impulsion complète. Cet effet d'ouverture rapide peut également générer trop de gain dans la soupape de contre-pression, ce qui entraîne une inefficacité et des bruits de claquement.

En combinant l’amortisseur et la soupape de surpression dans une seule unité technique, nous avons éliminé les problèmes les plus courants liés à l’installation pour un système plus efficace et simplifié.

VOIR LE HYBRIDE EN ACTION

Regardez notre directeur de l'ingénierie David McComb démontrer la Hybrid Valve ™ avec une pompe doseuse.

Il vous guidera à travers les performances de la pompe avec un amortisseur de pulsations seul, puis en série avec une soupape de contre-pression et enfin avec la nouvelle Hybrid Valve ™.

Comprendre les principes de la dynamique des fluides pour voir pourquoi la Hybrid Valve ™ offre les meilleures performances et donne à votre système la protection qu'il mérite.

SKU: n/a -

Blacoh

SANITARY PULSATION DAMPENERS

0 out of 5(0)FDA compliant materials and easy to clean for sanitary or food applications.

Designed for sanitary applications in chemical, industrial, water treatment, pharmaceutical and food/beverage industries, the Blacoh sanitary line of pulsation dampeners and surge suppressors feature specialized stainless steel bodies and tri-clamp fittings. Blacoh’s pulsation dampeners can remove up to 99% of pulsation and vibration, enhancing all-around performance and reliability of fluid flow and protect the system from costly maintenance and repair. Reduce pulsation, improve laminar flow, mitigate water hammer, shaking pipes, splashing, enhance pump performance and flow meter measurement by using one of these units. FDA compliant materials available, including polished and bead blasted 316L stainless steel surfaces. Tri-clamp inlets, optional T-handles, and autoclave safe wetted components provide for easy cleaning.

Features:

Maximum Pressure: 1,000 psi (68.9 bar)

Capacity: 4 cu in – 5 gallon (.066 – 19 L)

Body Materials: 30 RA Polished 316L Stainless Steel

Bead Blasted 316L Stainless Steel

Temperature: -20°F to +350°F (-29 °C to +177°C)

Inlet Port: Tri-Clamp Sanitary Fitting

Air Control Options: Automatic, Adjustable, Chargeable

Bladder Options: Food-Grade Buna, Food-Grade

Silicone, Food-Grade EPDM, PTFECommon Applications:

- Filling Lines

- Batch Pumping

- Breweries

- Pharmaceutical

- Food Processing

- Beverage

- Inks, Dyes & Coloring

- Cosmetics

- Soap/Detergent

- Flavoring

SKU: n/a -

Blacoh

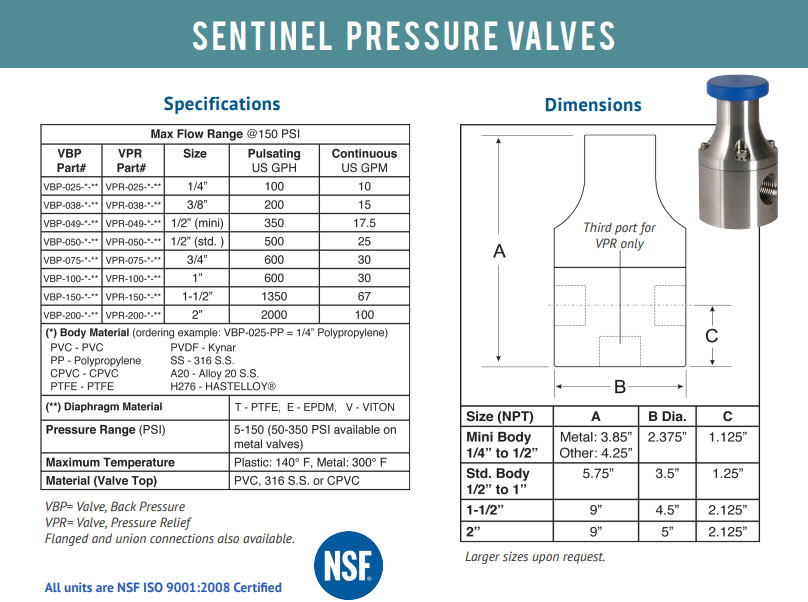

SENTINEL Diaphragm Back Pressure Valves

0 out of 5(0)Prevent siphoning and stabilize dosage rates with SENTINEL Diaphragm Back Pressure Valves

Diaphragm back pressure valves are designed to enhance the performance of pumping systems by applying a continuous back pressure to the system pump, while also acting as an anti-syphon valve. Robust construction ensures reliability in the rigorous service of municipal and industrial applications.

- Reliability and low cost

- Adjustable 5-150 psi for standard, 5-50 psi low pressure, or 50-350 psi high pressure

- Anti-siphon function

- Robust machined construction

- Vulcanized PTFE/EPDM diaphragm

- Full range of chemically resistant wetted materials

- Sizes from ¼” to 4” depending on model

Diaphragm back pressure valves apply positive discharge pressure to a metering pump system to prevent siphoning and eliminate varying dosage rates caused by fluctuating downstream pressure. The diaphragm is held against the valve seat by an internal spring. When the preset pressure is exceeded, the diaphragm is forced up and system fluid flows through the valve to the injection point. The valves are preset for 50 psi, however they are field adjustable from 5 to 150 psi, (optional up to 350 psi for high pressure) via the adjustment screw. Installation should be as close to the injection point as possible to prevent system line drainage, and it is most important that all pumping system equipment such as pulsation dampeners and pressure gauges are between the pump and back pressure valve

SKU: n/a